ICM full-automatic backflush filter, Shanghai Weixiu Filtering

Equipment Co., Ltd Telephone: 021-50117775

Application Scope

Industrial recirculated water: recirculated water, condensed water

and cooling water for blast furnace, rolling mill and conticaster in iron and

steel industry.

Filtering of raw water: sea water desalination, processing of

river water and surface water.

Environmental protection: pre-filtering of bag filters, strainer

core filters, UF filters and RO membrane filters.

Paper industry: raw water and white water filtering, nozzle

protection.

Filtering of central air conditioning system, petroleum and

chemical, automobile manufacture.

Design Features of the ICM Filter

The filter applies full-automatic continuous filtering, meeting

automatic operation requirements.

The filter is electrically driven. The reduction motor drives the

brush type cleaning system to clean impurities on the filter screen

automatically, maintaining the filtering function of the filter screen.

PLC control function: pressure difference cleaning, timing

cleaning, manual cleaning; The pressure difference cleaning is superior to other

methods. The filter can be connected to the central control room.

The excellent filtering effect of the filter has been proved. The

filter adopts stainless steel wedge type filter screen which provides excellent

cleaning effect and is wear-resistant.

The filter can replace the traditional bag filter, basket filter,

strainer core filter, vibrating screen filter, frame filter and stainless steel

filter in various fields.

Model | A(mm) | B(mm) | C(mm) | D(mm) | Inlet/outlet size | Size of discharging outlet | Maximum flow (m3/h) | Motor power (KW) |

WX-ICM219 | 1500 | 450 | 500 | 219 | DN50 | DN25 | 30 | 0.25 |

WX-ICM350 | 1530 | 510 | 500 | 350 | DN100 | DN25 | 50 | 0.4 |

WX-ICM450 | 1800 | 550 | 500 | 450 | DN150 | DN50 | 100 | 0.75 |

WX-ICM550 | 1900 | 625 | 500 | 550 | DN200 | DN50 | 125 | 1.0 |

WX-ICM650 | 2000 | 680 | 500 | 650 | DN250 | DN50 | 150 | 1.25 |

WX-ICM750 | 2200 | 740 | 500 | 750 | DN300 | DN50 | 180 | 1.5 |

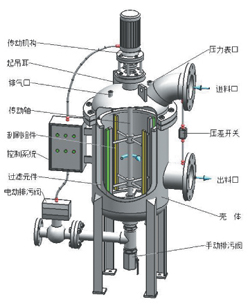

传动机构 | Transmission mechanism | 压力表口 | Pressure gauge interface |

起吊耳 | Hanging hole | 进料口 | Inlet |

排气口 | Air outlet | 压差开关 | Pressure difference switch |

传动轴 | Transmission shaft | 出料口 | Outlet |

控制系统 | Control system | 手动排污阀 | Manual blow-off valve |

过滤元件 | Filtering element | 壳体 | Shell |

电动排污阀 | Electric blow-off valve |

|

|

Structure and Working Principles of the ICM

Filter

The ICM full-automatic brush type self-cleaning filter is

comprised of reduction motor, filter shell, filtering elements, brush type

combined cleaning system, PLC controller and blow-off valve.

Raw materials enter the filter through the inlet and are filtered

by the filter screen from inside to outside. The filtered raw materials flow to

the outlet downward. Impurities that are larger than the gap of the filter

screen are retained. After a period of operation, the gap of the filter screen

is blocked by impurities. When the pressure difference reaches the set value,

the PLC monitors the signal and gives instructions. The reduction motor drives

the rotating scraper to clean dirt attached on the filter screen automatically

to maintain the filtering function of the filter screen and smoothness of the

gap of the filter screen. When impurities at the bottom of the filter increase,

you can open the blow-off valve at the bottom of the filter to discharge the

impurities to maintain the normal system pressure. The scraper of the scraper

type self-cleaning filter is properly designed with optimal scraping angle.

Under the driving of the reduction motor, the rotating scraper removes

impurities in the gaps of the filter promptly, without disassembling the filter

screen and maintaining smooth filtering of raw materials. The scraper type

filter is a full automatic filter comprised of stator, scraper-brush cleaning

system and spring. The pressure compensation of the spring is properly selected

to minimize the wear of the filter screen.

Working Principle of Self-Cleaning Filters

Water enters from the inlet, passes through the rough filter

screen which retains larger particles and then reaches the fine filter screen.

During filtering, dirt and impurities accumulate on the fine filter screen,

forming a layer of filtered impurities. Because impurities are accumulated on

the inside of the fine filter screen, pressure difference is formed between the

inside and the outside of the fine filter screen.

When the pressure difference reaches the set value, the

self-cleaning process starts automatically. During the process, clean water is

supplied without interruption. The purge valve is open. The water pressure in

the cleaning chamber and the suction device decreases sharply. With the pressure

difference between the filtering cartridge and the suction device, a suction

force is formed between the suction device and the cleaning chamber through the

suction nozzle, comprising a sewage suction process. Meanwhile, the electric

motor drives the suction pipe to carry out helical motion in the axial

direction. The combination of the axial motion and the helical motion of the

suction device completely cleans the inner surface of the filter screen. The

cleaning process takes only tens of seconds. The blow-off valve is closed when

the cleaning process ends. The full-automatic filter prepares for the next flush

cycle. Water to be processed enters the filter through the inlet. Impurities in

the water accumulate on the stainless steel filter screen, forming the pressure

difference. The pressure difference switch monitors the change of the pressure

difference at the inlet and the outlet. When the pressure difference reaches the

set value, the electric controller gives signals to the water control valve and

the driving motor. The motor drives the brush to rotate so as to clean the

filtering element. At the same tine, the control valve is open for discharging

wastes. The whole cleaning process takes only tens of seconds. When the cleaning

process ends, the control valve and the motor are stopped. The system returns to

the original state and enters the next filtering procedure.

After the filter is installed, technicians commission the filter

and set the filtering time and cleaning conversion time. When the water to be

processed enters the filter through the inlet, the full-automatic filter starts

working. When the set cleaning is reached, the electric controller gives signals

to the water control valve and the driving motor. The motor drives the brush to

rotate so as to clean the filtering element. At the same tine, the control valve

is open for discharging wastes. The whole cleaning process takes only tens of

seconds. When the cleaning process ends, the control valve and the motor are

stopped. The system returns to the original state and enters the next filtering

procedure.

Water enters the filter through the inlet, passes through the

rough filter screen which retains larger particles and then reaches the fine

filter screen. After fine particles are filtered by the fine filter screen, the

clean water is discharged through the outlet. During filtering, dirt and

impurities accumulate on the inside of the fine filter screen. Thus, pressure

difference is formed between the inside and the outside of the fine filter

screen. When the pressure difference reaches the set value, the cleaning process

starts automatically. The blow-off valve is open. The hydraulic motor chamber

and the hydraulic cylinder of the main pipe release pressure and discharge the

water. The pressure in the hydraulic motor chamber and the suction pipe

decreases sharply. Because of the negative pressure, dirt on the inner wall of

the fine filter screen is suctioned through the suction nozzle and enters the

hydraulic motor chamber through the hydraulic motor. Then the dirt is discharged

from the blow-off valve. Thus the sewage suction process is formed. When water

passes through the hydraulic motor, the motor drives the suction pipe to rotate.

The piston of the hydraulic cylinder drives the suction pipe to carry out axial

motion. The combination of the axial motion and the helical motion of the

suction device completely cleans the inner surface of the filter screen. The

whole cleaning process takes tens of seconds. After the cleaning process ends,

the blow-off valve is closed. The increased water pressure pushes the piston of

the hydraulic cylinder to the original position. The self-cleaning filter

prepares for the next cleaning cycle. During the cleaning process, the normal

filtering of the filter is not interrupted.