BCM full-automatic backflush filter, Shanghai Weixiu Filtering Equipment Co., Ltd Telephone: 021-50117775

Application Scope:

Domestic water supply, industrial water supply, filtration and ultrafiltration, reverse osmosis, softening, ion exchange, recirculated water for oil fields, recirculated cooling water, wastewater reuse, purification of underground water and surface water, circulating water of central air-conditioning systems and boilers, swimming water and landscape water, civil facilities, spraying water for greenbelts, and agricultural irrigation.

Full-automatic Filter Technology and Features:

Filters have high filtering precision and thus ensure stable water quality.

Filters realize full-automatic backflush through self retrieval and straining and thus can handle unstable water quality fluctuation without manual interference.

The control system of filters is sensitive and accurate and can automatically adjust the pressure difference value of the backflush according to water sources and filtering precision.

Filters can be cleaned thoroughly and efficiently with highly recoverable systems and durable filter screen which does not need to be replaced.

During the automatic backflush, each filter screen (group) carries out backflush in turn to ensure safety and efficient flush of filter screens while other filter screens are not affected and continue filtering.

Filters apply blow-off valves and thus feature short backflush time and low water consumption, saving water and energy.

Filters are compactly and properly designed, covering small areas and convenient in installation and transportation.

Filters have few wearing parts and no consumable and thus feature low operation and maintenance cost and easy operation and management.

|

Model

|

A(mm)

|

B(mm)

|

C(mm)

|

D(mm)

|

Inlet/outlet size

|

Size of discharging outlet

|

Maximum flow (m3/h)

|

|

WX-BCM350

|

1720

|

265

|

660

|

350

|

DN80、100

|

DN50

|

56

|

|

WX-BCM400

|

1760

|

265

|

680

|

400

|

DN100、125

|

DN50

|

100

|

|

WX-BCM500

|

1860

|

290

|

715

|

500

|

DN150

|

DN65

|

150

|

|

WX-BCM600

|

1930

|

290

|

755

|

600

|

DN200

|

DN65

|

250

|

|

WX-BCM700

|

2040

|

335

|

755

|

700

|

DN250

|

DN65

|

400

|

|

WX-BCM800

|

2105

|

335

|

770

|

800

|

DN300

|

DN80

|

500

|

|

WX-BCM1000

|

2220

|

335

|

800

|

1000

|

DN400

|

DN80

|

700

|

|

WX-BCM1200

|

2360

|

365

|

825

|

1200

|

DN450

|

DN100

|

1000

|

|

WX-BCM1400

|

2500

|

400

|

850

|

1400

|

DN500

|

DN100

|

1450

|

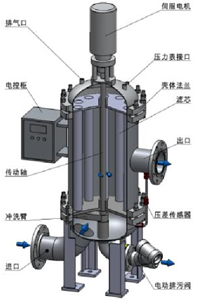

Backflush Process of Full-automatic Filters

The reduction motor drives the flush arm to rotate through the jackshaft and the photoelectric sensor controls the rotating angle of the flush arm to align it with the flushed filter element.

The blow-off valve starts, forming the pressure difference between the outside of the flushed filter screen (cleaning side) and the blow-off valve.

Under the pressure difference, fluids on the cleaning side flow from the outside to the inside through the flushed filter screen to realize backflush. Pollutants on the inside accumulate on the inside of the filter screen are flushed away and discharged from the discharging outlet of the filter.

The backflush time of each filter screen is pre-set. When the pre-set backflush time is reached, the blow-off valve is closed and the backflush process of the filter screen is finished. The reduction motor again drives the flush arm to rotate to backflush the next filter screen. The blow-off valve starts again. The process proceeds until all filter screens are backflushed.

After the backflush of all filter screens is complete, the flush arm returns to the original position under the control of the zero position switch. A backflush cycle ends.

Because the backflush is carried out for all filter screens one by one, the filter can keep filtering liquids during the backflush process.

Setting of Backflush Time of Full-automatic Filters

Pressure difference setting: the pressure difference gauges of filters have two signaling points for pressure difference setting. The first signaling point is used to set the backflush process of filters. The second signaling point is used to monitor the working state of filters and is optional.

Time setting: the time setting device is installed on the control box of filters to set the period of the backflush process according to users' requirements.

The pressure difference setting and time setting are the settings of full-automatic backflush filters. Two settings coexist and the pressure difference setting is superior to the time setting.

Manual start: In addition to pressure difference setting and time setting automatic backflush processes, the backflush process can also be started by pressing the TEST key. This method is used for commissioning and repairing.

Description of the Filtering Process

When liquids flow from the inside of the filter screen to the outside of the filter screen, solid particles are retained at the inside of the filter screen. The pressure difference between the polluted side and the clean side increases gradually. When the pressure difference reaches the set value, the pressure difference gauge gives signals and the filter starts the full automatic backflush process.

Innovations of Filtering Technology

Filters apply 304 stainless steel filter screens which have high strength and high precision and are corrosion-resisting with maximum filtering precision up to 25 μm.

Filters adopt patented internal mechanical structure and thus realize true high-pressure backflush. With high-pressure backflush, impurities retained by the filter screen can be easily and thoroughly cleaned without dead corners and attenuation of flux, ensuring high filtering efficiency and lasting service life.

The inlet and outlet of filers are flanged and can be rotated freely for direction adjustment and easy installation.

The electric system of filters applies centralized control and can be controlled remotely.

|

进气口

|

Air inlet

|

气体法兰

|

Gas flange

|

|

电控柜

|

Electric control cabinet

|

滤芯

|

Filtering element

|

|

传动轴

|

Transmission shaft

|

出口

|

Outlet

|

|

冲洗臂

|

Flushing beam

|

进口

|

Inlet

|

|

伺服电机

|

Servo motor

|

压差传感器

|

Pressure difference sensor

|

|

压力表接口

|

Pressure gauge interface

|

电动排污阀

|

Electrical blow-off valve

|

Functions and Application of Filters

The filter is mainly used for purifying water, especially the microstraining field that has high requirement on water quality. The filter is used to remove sand, clay, iron rust, suspended matters, alga, biological slime, corrosion products, macromolecular bacteria, organic substances, other small particles and impurities such as oil to purify water.

Working Principle of Self-Cleaning Filters

Water enters from the inlet, passes through the rough filter screen which retains larger particles and then reaches the fine filter screen. During filtering, dirt and impurities accumulate on the fine filter screen, forming a layer of filtered impurities. Because impurities are accumulated on the inside of the fine filter screen, pressure difference is formed between the inside and the outside of the fine filter screen.

When the pressure difference reaches the set value, the self-cleaning process starts automatically. During the process, clean water is supplied without interruption. The purge valve is open. The water pressure in the cleaning chamber and the suction device decreases sharply. With the pressure difference between the filtering cartridge and the suction device, a suction force is formed between the suction device and the cleaning chamber through the suction nozzle, comprising a sewage suction process. Meanwhile, the electric motor drives the suction pipe to carry out helical motion in the axial direction. The combination of the axial motion and the helical motion of the suction device completely cleans the inner surface of the filter screen. The cleaning process takes only tens of seconds. The blow-off valve is closed when the cleaning process ends. The full-automatic filter prepares for the next flush cycle.

Water to be processed enters the filter through the inlet. Impurities in the water accumulate on the stainless steel filter screen, forming the pressure difference. The pressure difference switch monitors the change of the pressure difference at the inlet and the outlet. When the pressure difference reaches the set value, the electric controller gives signals to the water control valve and the driving motor. The motor drives the brush to rotate so as to clean the filtering element. At the same tine, the control valve is open for discharging wastes. The whole cleaning process takes only tens of seconds. When the cleaning process ends, the control valve and the motor are stopped. The system returns to the original state and enters the next filtering procedure.

After the filter is installed, technicians commission the filter and set the filtering time and cleaning conversion time. When the water to be processed enters the filter through the inlet, the full-automatic filter starts working. When the set cleaning is reached, the electric controller gives signals to the water control valve and the driving motor. The motor drives the brush to rotate so as to clean the filtering element. At the same tine, the control valve is open for discharging wastes. The whole cleaning process takes only tens of seconds. When the cleaning process ends, the control valve and the motor are stopped. The system returns to the original state and enters the next filtering procedure.

Water enters the filter through the inlet, passes through the rough filter screen which retains larger particles and then reaches the fine filter screen. After fine particles are filtered by the fine filter screen, the clean water is discharged through the outlet. During filtering, dirt and impurities accumulate on the inside of the fine filter screen. Thus, pressure difference is formed between the inside and the outside of the fine filter screen. When the pressure difference reaches the set value, the cleaning process starts automatically. The blow-off valve is open. The hydraulic motor chamber and the hydraulic cylinder of the main pipe release pressure and discharge the water. The pressure in the hydraulic motor chamber and the suction pipe decreases sharply. Because of the negative pressure, dirt on the inner wall of the fine filter screen is suctioned through the suction nozzle and enters the hydraulic motor chamber through the hydraulic motor. Then the dirt is discharged from the blow-off valve. Thus the sewage suction process is formed. When water passes through the hydraulic motor, the motor drives the suction pipe to rotate. The piston of the hydraulic cylinder drives the suction pipe to carry out axial motion. The combination of the axial motion and the helical motion of the suction device completely cleans the inner surface of the filter screen. The whole cleaning process takes tens of seconds. After the cleaning process ends, the blow-off valve is closed. The increased water pressure pushes the piston of the hydraulic cylinder to the original position. The self-cleaning filter prepares for the next cleaning cycle. During the cleaning process, the normal filtering of the filter is not interrupted.